Products

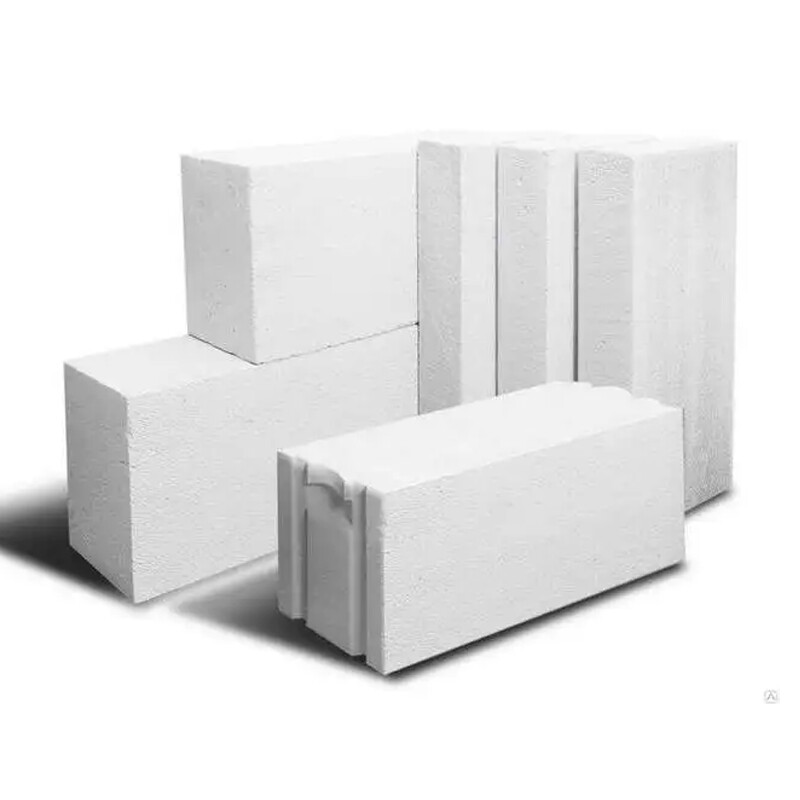

Autoclaved fly ash bricks and fly ash bricks are made of fly ash or other slag or fly ash sand as raw materials, with lime, gypsum and aggregate added, and are made through processes such as blank preparation, pressing and molding, and efficient steam curing. The complete set of autoclaved brick equipment includes: mixer, digester, autoclaved brick machine, wheel roller, autoclave and other main equipment, as well as box feeder, screw conveyor, crawler bucket, aggregate scale, belt conveyor, maintenance trolley, ferry car and other auxiliary equipment. The frost resistance, corrosion resistance, compressive strength and other properties of autoclaved bricks are superior to the artificial stone of solid clay bricks. The specifications and dimensions of the bricks are exactly the same as those of ordinary solid clay bricks, which are 240mm x 115mm x 53mm, so autoclaved bricks can directly replace solid clay bricks. It is a new type of wall material that the country vigorously develops and applies.

The main materials of autoclaved sand-lime bricks are sand (about 90%) and lime (nearly 10%), as well as some color matching materials. They are made through three stages: blank preparation, pressing and autoclaving. The bricks are available in two types: solid and hollow.

Dongying Huawen New Building Materials Co., Ltd.

First class quality service and professional after-sales team.

Beidian Village, Daozhuang Town, Guangrao County

Get in Touch

*We respect your confidentiality and all information are protected.